产品详情

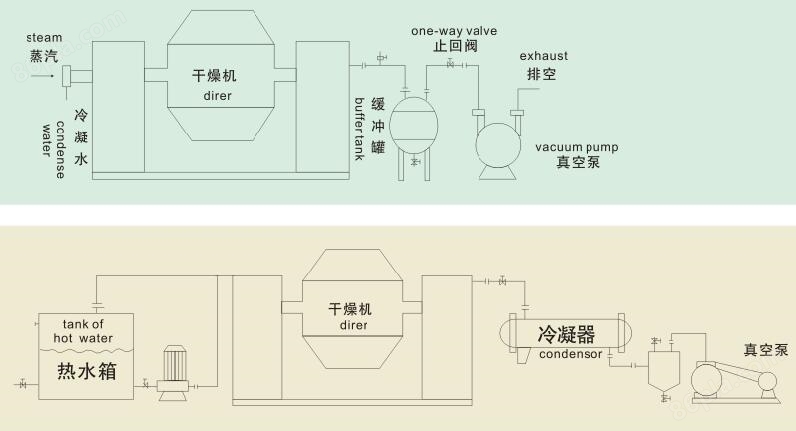

本干燥机是使用设有夹套对称圆锥形容器作回转运动,并借助于容器内体呈圆锥体的倾斜不断翻动、混合,通过设有热介质密封机构将热源通入夹套,对物料进行传导加热的同时物料在整个烘干工程中均处于真空状态进行干燥脱水。广泛应用于医药、食品、化工、生物工程、冶金粉末、环保等物料,在真空干净环境下强制低温脱水。

For this drier, the materials are dried and dehydrated by rotating the symmetricaltaper container with jacket, turning and mixing the material by using the cone incline in the container, passing the heat source into the jacket by sealing mechanism with thermal medium, and conductively heating the material while keeping the materials in vacuum state during the whole drying process. It is widely applied in the forced low temperature dehydration in vacuum and clean environment in the medicine, food, chemical, bioengineering, powder metallurgy and environmental protection sectors.

1.广泛适用于除浆状、粘性大的物料以外的产品的低温真空烘干脱水。

2.本装置系统广泛适用于干燥含水或含结晶水以及其他溶剂的物料,而且溶剂还可以回收利用。

3.特别适用于热敏性物料的干燥,加热方式也可以据物料特性用蒸汽、导热油、电加热、热水,还可据工艺要求调节真空度、温度、烘干时间。

4.特别适用于对晶体形状有严格要求、出料干净、受热均匀的物料的烘干,可以获得含水率低于0.5%-0.1%以下的水分要求。

5.适用于加热烘干,也适用于冷却,干燥过程对环境无污染,还可以用来加热+混料等多种用途。

1.It is widely applied in the low-temperature vacuum drying and dehydration of products except paste and viscous materials.

2.This equipment system is widely applied in the drying of materials containing water, crystal water and other solvents, in which the solvents may be recycled.

3.It is especially applicable to drying of heat-sensitive materials; the heating can usesteam, conduction oil, electricity and hot wateraccording to physical property of the materials, and the vacuum degree, temperature and drying time may be adjusted according to the process requirements.

4.It is especially applicable to the drying of materials heated uniformly with strict requirements to crystal shape, clean discharge, and water content of lower than 0.5%-0.1%.

5.It is applicable to heating and cooling drying, and multiple purpose of heating + mixing; no environmental pollution will be caused during the drying.

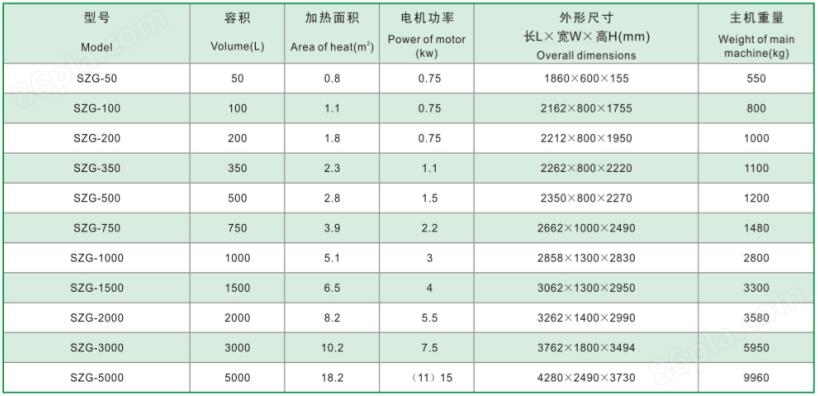

注:

1、对于干燥前后容积有很大变化的物料。其装料系数可相应增减,但总装料容积应控制在≤50%。

2、2000型转速:6转/分,3000、5000型4转/分。

3、搪瓷内胆规格基本相同。

4、特殊需要可另行设计。

5、工作温度:罐内≤100℃。

Note: 1. For the material which changes a lot in volume before and after drying, the charging coefficient can increase or decrease correspondingly but the total charging volume shall be controlled to be ≤50%.

2. Rotation speed of 2000 type: 6 turns/min, and 4 turns/min for type 3000 and 5000.

3. The specifications of enamel liners are basically identical.

4. Designs can be provided separately for special needs.

5. Working temperature:≤100℃ inside the tin.

摘要:双锥真空干燥机一、工作原

[详细]

摘要:双锥真空干燥机一、工作原

[详细]

摘要:一、工作原理及应用范围介

[详细]

摘要:一、工作原理及应用范围介

[详细]

摘要:一、工作原理与应用范围介

[详细]

摘要:一、工作原理与应用范围介

[详细]

摘要:一、工作原理及应用范围介

[详细]

摘要:一、工作原理及应用范围介

[详细]

摘要:一、工作原理及应用范围介

[详细]

摘要:一、工作原理及应用范围介

[详细]

摘要:一、工作原理与应用范围介

[详细]

摘要:一、工作原理与应用范围介

[详细]

摘要:一、工作原理与适用范围Wor

[详细]

摘要:一、工作原理与适用范围Wor

[详细]

摘要:大风量烘箱一、工作原理与

[详细]

摘要:大风量烘箱一、工作原理与

[详细]